Description

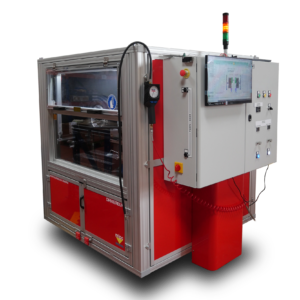

The plate roller consists of three parts:

1/ A molded frame guides a carriage driven longitudinally by an electro-reducer behind it. This carriage carries a balanced pendulum beam that is movable in a vertical plane by means of a hydraulic cylinder. The balance is equipped with a fixed shaft, mounted perpendicular to the carriage trajectory, on which slides a “wheel carrier” whose position is marked. This system gives the tire three movements: longitudinal, vertical and transverse. The front of the frame is equipped with an electric lifting paver screed that pushes the material upwards as it is compacted. This paver screed, whose top adapts to the dimensions of the slab to be compacted, is controlled by a main screw coupled to four wheel nuts, movable on four screws attached to the frame. On the side, an oleo-pneumatic compartment includes an air conditioning unit: filter, lubricator and oleo-pneumatic grade-separated interchange, solenoid valve.

2/ The console: presented separately from the paver screed, it gathers all the ordering and monitoring parts of the manufacturing process.

3/ Compaction accessories: these are mainly fusegates, molds, base plates, hubs fitted with tyres.