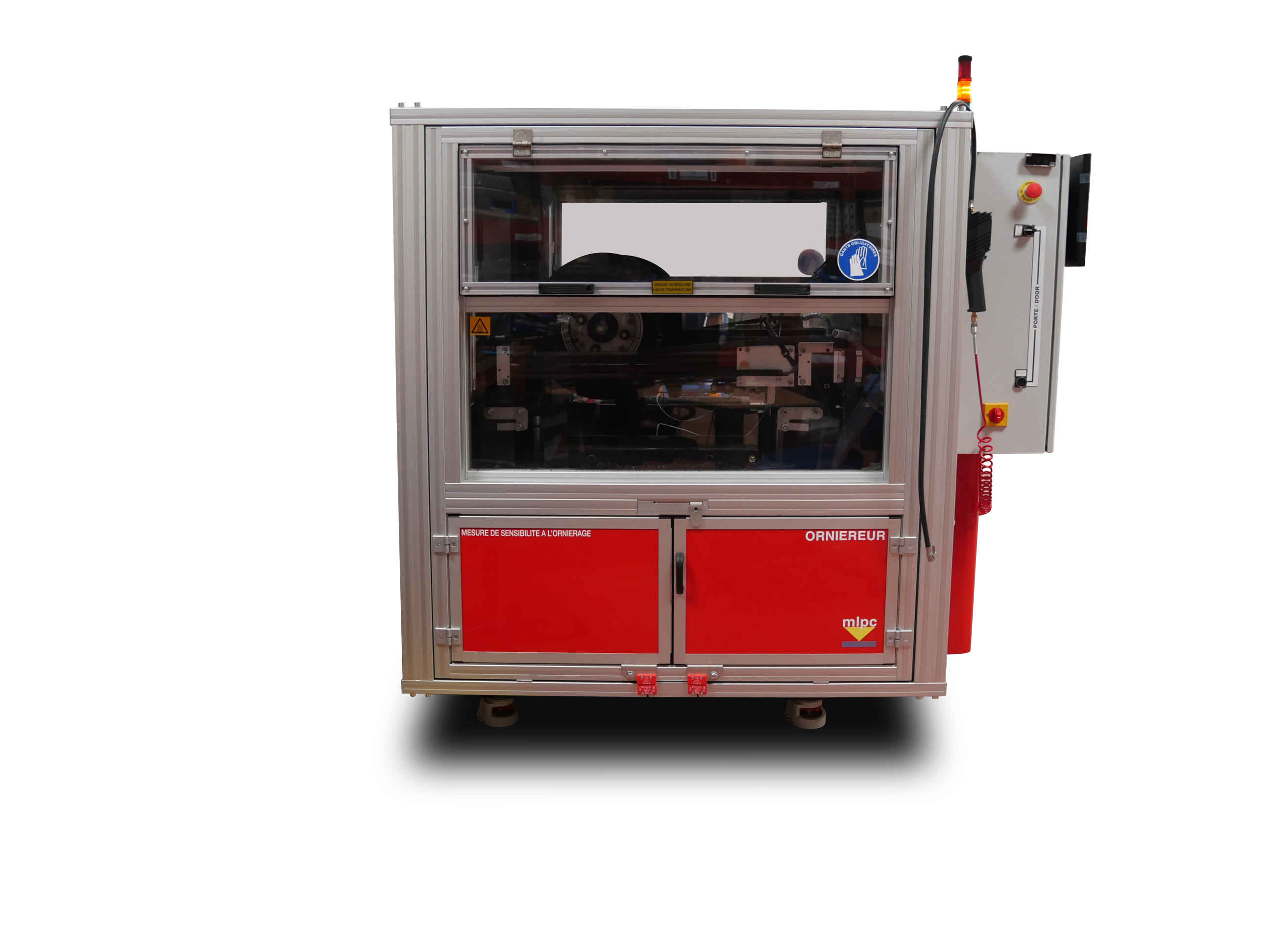

Description

Laboratory equipment designed to study the rutting of asphalt mixes under conditions comparable to the stresses on pavements under traffic, according to standard EN 12697-22.

Two asphalt specimens are simultaneously subjected to repeated passages of a wheel equipped with a tire, under a certain load and under controlled temperature. It is possible to integrate or not to the wheel an angle allowing to introduce a lateral skidding effect.

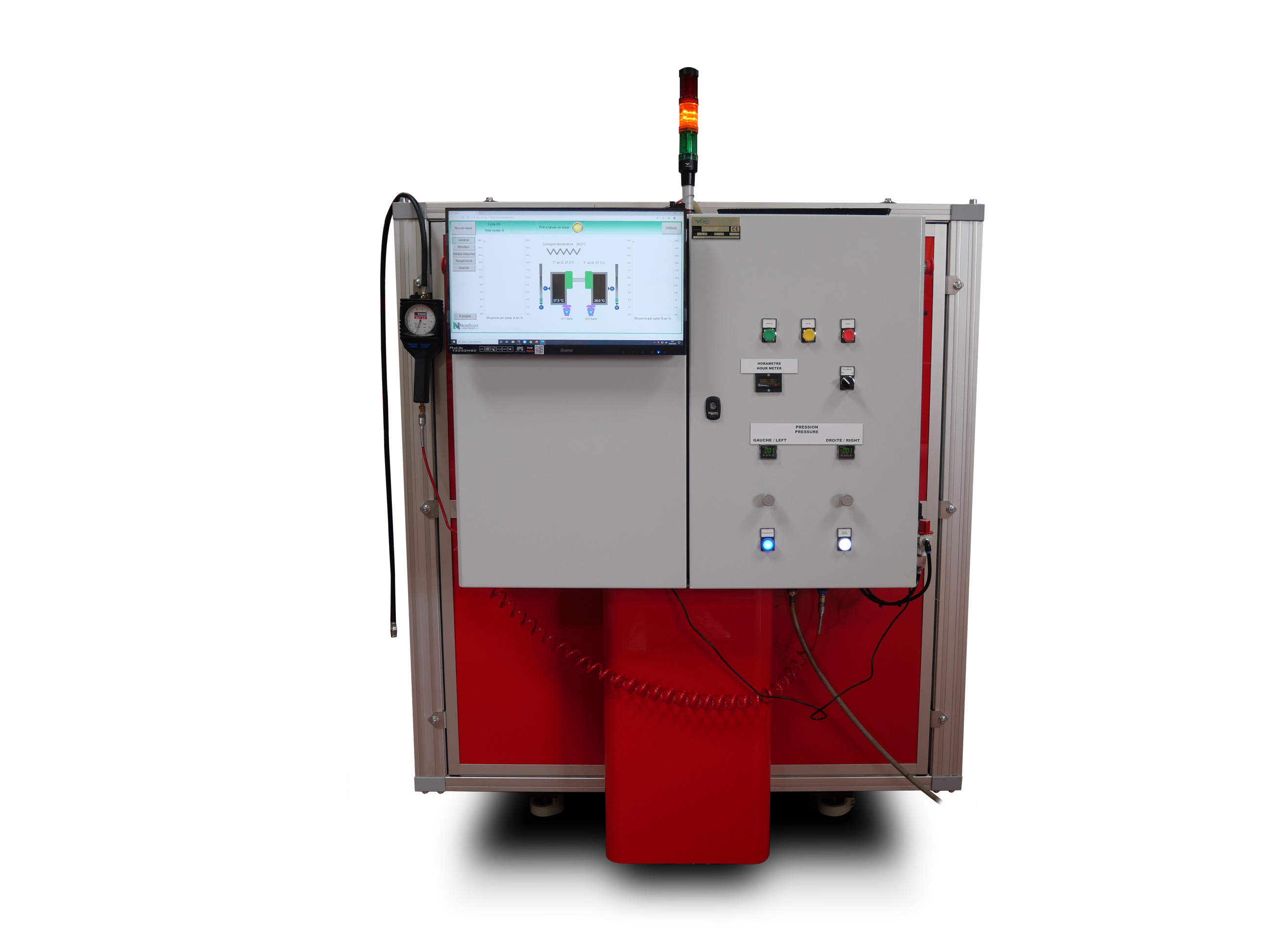

Automation cuts the testing time by a factor of three and saves 50% of the laboratory worker’s time. The equipment therefore quickly pays for itself compared to a traditional rutting machine.

Many copies of Orniéreur mlpc® have been distributed throughout the world, it is an essential tool for the formulation of asphalt mixes. The latest generation allows you to go further: higher temperature rise, new cowling, control and ergonomics redesigned for the needs of today’s laboratories.