Expansion of the Vectra range: The VDG40 is available at NextRoad!

Want to save time controlling the granularity and shape of granular mixtures?

The VDG40 is a «Videogranulometer» device that quickly measures the granularity and shape of road construction and civil engineering materials. This device replaces the traditional method of sifting aggregates and it happens to be faster than this one. The VDG40 can analyze very fine particles of aggregates that can be rejected during sieving, with excellent fidelity. Thanks to this device, the washing and drying of materials can be avoided, which causes a significant time saving due to repetitions.

What standard does this device work with?

This MLPC equipment meets the criteria of the XP P 18-566-2002 standard and is selected for

XP P 18-540 as an alternative test for particle size distribution.

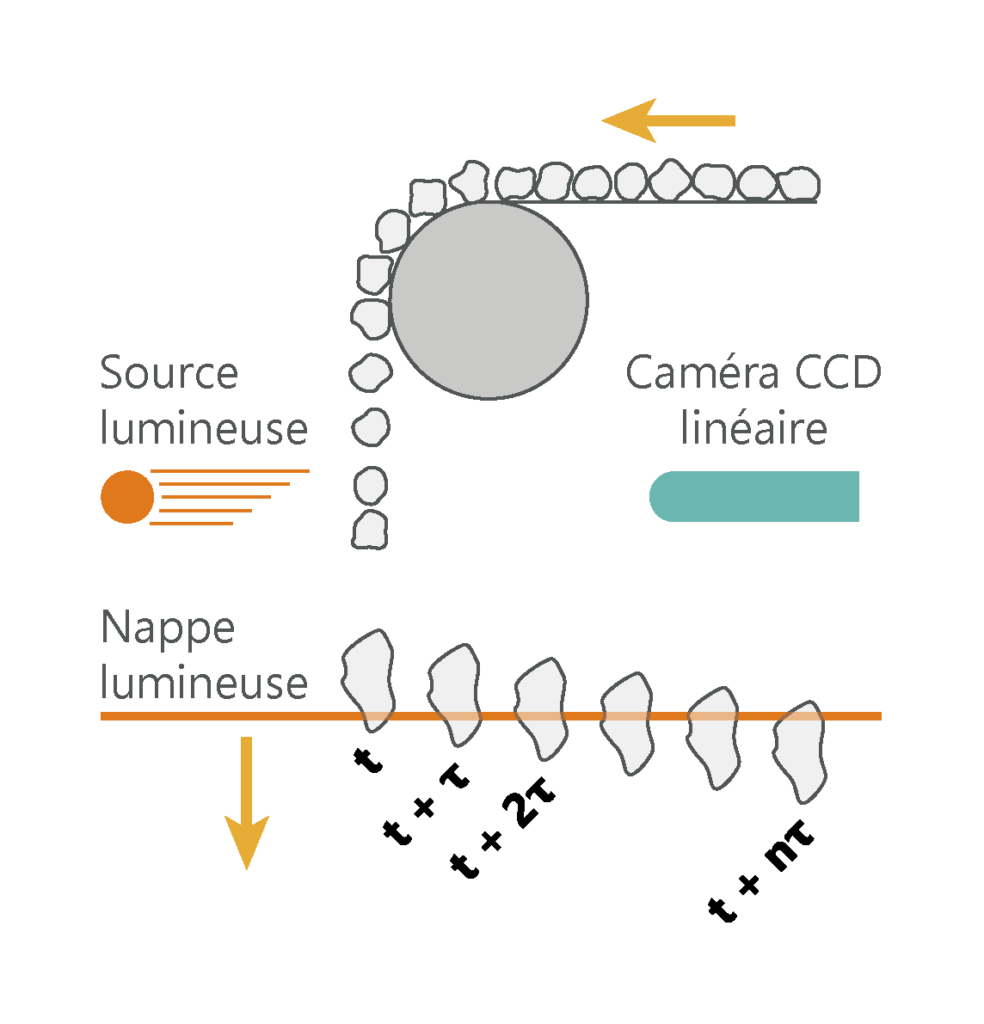

VDG 40 Block Diagram

How it Works ?

The VDG40 enables the VDG particle size curve to be determined quickly and precisely by image analysis.

- First, the camera will project a shadow constituting the contour of said particle.

- Then, it will determine the coordinates of said contour of the shadow of the analyzed particle.

- Then, the coordinates will be processed to approach the contour by several consecutive segments.

- To conclude, with all of these data collected and processed. The VDG40 will determine a criterion of morphology of the particle studied, divided by a treatment of relative positions of at least two consecutive segments.

What to remember:

- Speed of sample analysis

- Optional sample wash = time saving

- Compliant with XP P 18-566 (July 2002)

- Determination of a very fine particle granularity (fraction from 1mm to 63mm)

- Regular monitoring of quarry production

Join us on LinkedIn : https://www.linkedin.com/company/nextroad/