Description

The IMAG is an automatic device for measuring the skid resistance of aeronautical pavements. It is the result of a cooperation between the Civil Aviation Technical Service / General Directorate of Civil Aviation and Aéroports De Paris.

The IMAG is covered by patent 89.16834. A measuring wheel, weighted and towed at a constant speed (up to 140 km/h), is braked according to a selected slip rate (0% to 100%).

The use of IMAG allows:

An operational evaluation of skid resistance in winter under operating conditions.

A functional evaluation of skid resistance outside the winter season (measure on water film): management of runways and taxiways (e.g., need for degumming).

Composition:

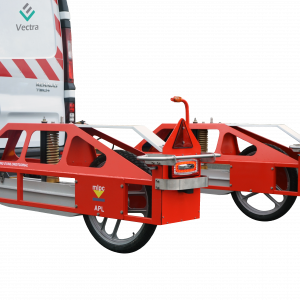

3-wheel trailer towed by a motor vehicle. Supporting frame with 2 support wheels equipped with speed sensor

(speed and distance measurement).

Measuring frame articulated on the carrier frame comprising a measuring wheel equipped with a PIARC smooth tyre:

- Dimensions 165 x 380 PIARC type

- Inflation pressure: 150 kPa

- Load on the measuring wheel: 175 daN.

In addition, the device measures temperatures:

- Pavement surface

- Ambient air

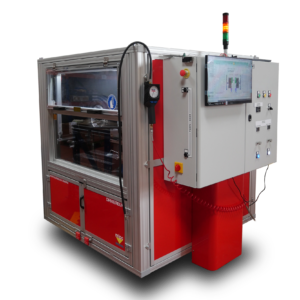

Measure of friction coefficient system

Braking of the measuring wheel of the moving device at a variable slip rate.

Continuous measurement of the horizontal traction force on the wheel, the braking torque, and the dynamic load on the wheel. In order to obtain an excellent representative sample of the skid resistance as well as excellent reliability of the measurement, the IMAG carries out 1 measurement every 5 mm, that is to say 200,000 measurements per km.

Processing of the measurement signal and conversion into two friction coefficients: pure friction coefficient (related to the quality of the surface only) and a drag friction coefficient (related to the presence of “contaminants” on the road):

- Measuring speed up to 140 km/h

- Usual speeds: 40, 65 and 95 km/h

Use:

Integrated control system for the operating elements of the measuring device.

The link between the IMAG and the microcomputer, which allows the measurements to be viewed in real time, is made via a wireless link.

Tractor vehicle, equipped with a standard hitch, of sufficient power to allow the test speed to be reached quickly.

Additional equipment:

An autonomous wetting system is to be implemented for a functional use (out of winter season) of the IMAG. This system ensures a constant wetting in front of the measuring wheel, whatever the speed of the vehicle.