Description

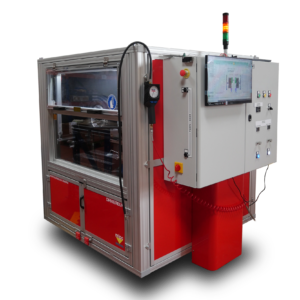

The design of this machine is the result of 20 years of experience. It guarantees a very high stiffness of the specimen receptacle and its constancy over 360°, two parameters which contribute to the quality of the test and its high reproducibility whatever the characteristics of the tested materials.

The dissociation of the two complementary functions of shearing (Fc) and clamping (Fv) gives this machine very high accessibility to all its active parts.

The PCG 3 consists of two parts:

- A test modulus

- An order – control – acquisition system

The test modulus combines the shear and clamping functions:

- The shearing function is included in the upper part of the machine which receives the specimen. A vernier associated with stops allows the instantaneous finishing of the half angle at the top of the turning cone. The gyration is ordered by an electric motor. A set of four bearings ensures the decoupling of the rotation and gyration functions,

- The shear force can be measured by means of a compression sensor placed on the tilt adjustment axis.

- The clamping function forms the lower part of the machine, and consists essentially of a servo-controlled electric cylinder whose guidance has been optimised so as not to affect the selected half-angle during the test. The coupling between the shear and clamping functions is ensured by a special plate that rests on the pad forming the bottom of the specimen.

The order-control-acquisition system comprises:

- An electrical cabinet attached to the machine

- A computer with PCG 3 software

- A specific PCG 3 operating software application

An optional graded aggregate emulsion kit

The graded aggregate emulsion kit allows tests to be carried out on cold mixtures. The extruded water is continuously weighed according to the number of gyrations.